Offshore Structural Steel Detailing: Growing Demand in the USA, Canada & Australia

The landscape of structural steel fabrication is rapidly evolving. In 2025, an increasing number of fabricators across the USA, Canada, and Australia are choosing to outsource their steel detailing needs—and for good reason.

Outsourcing provides access to a global pool of specialized talent, ensuring precision and efficiency in every project. With advancements in technology and communication, working with remote detailing experts has never been easier or more cost-effective. Companies are able to focus their internal resources on core fabrication tasks while leveraging the expertise of dedicated detailers who stay up-to-date with industry standards and software innovations. This not only accelerates turnaround times but also improves accuracy, reducing costly errors during erection.

Outsourced steel detailing firms often offer scalable solutions that can adjust seamlessly to fluctuating project demands—whether it’s a small retrofit or a complex high-rise development. The result is increased flexibility for fabricators navigating tight schedules and labor shortages. In today’s competitive market, embracing outsourcing isn’t just a matter of convenience; it’s quickly becoming an essential strategy for staying ahead and delivering exceptional results to clients worldwide.

Here are the top drivers behind this shift:

1. Rising Labor Costs in Developed Countries

Salaries for experienced detailers, modelers, and checkers continue to rise in developed nations. Outsourcing gives fabricators access to the same technical expertise at a fraction of the cost, without any compromise on quality. By partnering with reputable outsourcing firms, fabricators can tap into a global talent pool that is highly skilled and up-to-date with the latest industry standards. This approach not only drives significant cost savings but also allows companies to scale their operations quickly in response to project demands. Additionally, outsourcing reduces the burden of recruitment and training, enabling fabricators to focus resources on core business activities and strategic growth. In an increasingly competitive market, leveraging outsourced technical services provides a clear advantage for those seeking efficiency without sacrificing precision or reliability.

2. Shortage of Experienced Steel Detailers Locally

The shrinking pool of qualified steel detailers is a growing concern. Offshore partners bridge this skills gap, providing experienced professionals who are immediately available for both new and ongoing projects. By leveraging the expertise of offshore partners, companies can maintain project momentum and ensure that deadlines are consistently met, even in the face of domestic talent shortages. These professionals bring not only technical proficiency but also fresh perspectives that can enhance design efficiency and drive innovation. Additionally, engaging with offshore teams often results in cost savings without compromising on quality, allowing firms to allocate resources more strategically across their operations. Ultimately, partnering with skilled detailers from abroad is a practical solution for sustaining growth and competitiveness in an increasingly demanding industry landscape.

3. Faster Turnaround Through 24/7 Workflow

Time zone differences mean your project never sleeps. While your local team rests, offshore detailers keep progress moving—enabling you to meet the tightest schedules and deliver projects faster.

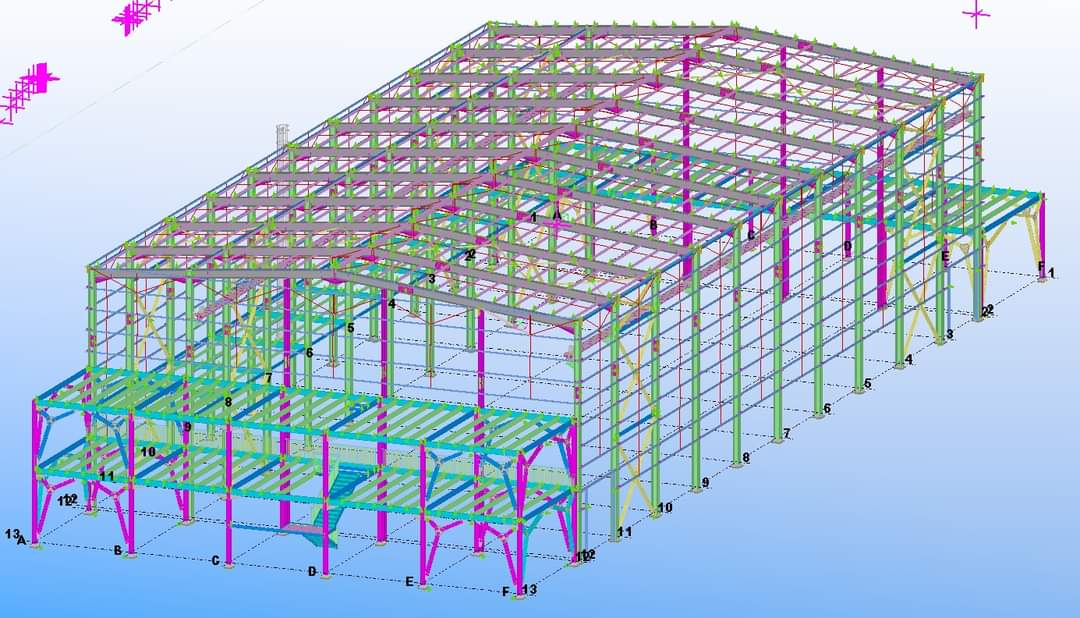

4. Access to Advanced Software Without High Licensing Costs

Industry-leading software like Tekla, SDS2, and Advance Steel comes with significant licensing fees. Offshore partners already have these tools in place, allowing you to benefit from cutting-edge technology without the heavy investment. By leveraging the resources of experienced offshore partners, your company can access the same advanced software capabilities used by top industry players, but at a fraction of the cost. This approach not only eliminates the need for expensive upfront purchases and ongoing maintenance fees but also ensures your projects benefit from up-to-date features and seamless integration. Ultimately, working with offshore teams who already utilize these powerful platforms enables you to focus on quality results and project efficiency—all while keeping your budget in check.

5. Ability to Quickly Scale Resources

Project workloads fluctuate. Outsourcing enables you to scale up or down instantly, adapting to large contracts or slow periods—without the hassle of hiring or layoffs.

6. Reduced Overhead and Operational Expenses

Outsourcing dramatically lowers costs associated with full-time staff—think benefits, ongoing training, hardware, and office space. This streamlined approach keeps your operations lean and highly efficient.

7. High-Quality Output Backed by Strong QA/QC Systems

Reputable offshore firms employ rigorous quality assurance and control procedures. This ensures accurate, fabrication-ready drawings, reduces RFIs, and minimizes costly rework.

8. Compliance with International Standards

Top offshore detailers are well-versed in AISC, CISC, AS/NZS, NISD, and OSHA standards. You receive deliverables that fully comply with local codes and industry requirements.

9. Better Focus on Core Fabrication Activities

By delegating detailing work, your team can concentrate on what they do best—production, project management, client coordination, and winning new business—boosting your overall productivity and efficiency.

10. Competitive Advantage in Bidding and Delivery

Lower detailing costs and faster project turnaround give you a decisive edge. You can submit more competitive bids, win more contracts, and deliver projects faster than competitors relying solely on local detailing resources.

In summary:

Outsourcing structural steel detailing is no longer just a cost-saving tactic—it’s a strategic business move. In 2025, fabricators in developed countries who embrace this model are better positioned to thrive, outpace competitors, and deliver exceptional value to their clients. If you want to stay competitive and future-ready, it’s time to consider the offshore advantage.